Redflow

About Redflow

Redflow Limited, a publicly-listed Australian company (ASX: RFX), produces small 10kWh zinc-bromine flow batteries that tolerate daily hard work in harsh conditions. Redflow batteries are designed for high cycle-rate, long time-base stationary energy storage applications in the telecommunications, commercial & industrial and high-end residential sectors, and are scalable from a single battery installation through to grid-scale deployments. Redflow batteries are sold, installed and maintained by an international network of energy system integrators. Redflow’s smart, self-protecting batteries offer unique advantages including secure remote management, 100 per cent daily depth of discharge, tolerance of high ambient temperatures, a simple recycling path, no propensity for thermal runaway and sustained energy delivery throughout their operating life.

- Details

- In Redflow

- /

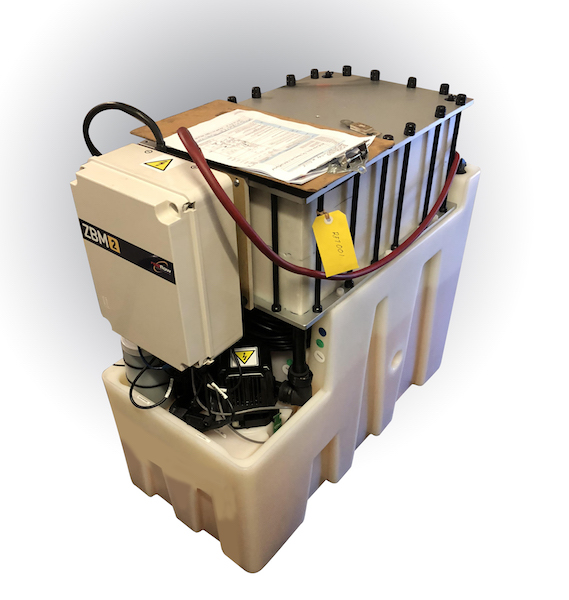

ZBM2 zinc-bromine flow battery with a battery stack made by Redflow factory in ThailandAustralian battery company Redflow Limited (ASX: RFX) has completed the first ZBM2 batteries using battery stacks made by its new Thailand factory, which are now ready for shipment to customers.

ZBM2 zinc-bromine flow battery with a battery stack made by Redflow factory in ThailandAustralian battery company Redflow Limited (ASX: RFX) has completed the first ZBM2 batteries using battery stacks made by its new Thailand factory, which are now ready for shipment to customers.

The battery stack is the critical part of the Redflow ZBM2 zinc-bromine flow battery, with electrodes that charge the battery by depositing zinc on a membrane and discharge it by reversing that process.

At Redflow’s Brisbane headquarters, the Thai-made battery stacks were installed on existing ZBM2 battery ‘tank sets’ and connected to performance-testing equipment. After passing pre-delivery tests, these complete batteries are now scheduled for delivery to supply existing customer orders. Redflow will continue to assemble, test and deliver limited quantities of ZBM2 batteries with Thai-produced battery stacks until it starts end-to-end manufacturing and testing of complete batteries in Thailand by June.

- Details

- In Redflow

- /

Australian battery company Redflow Limited (ASX: RFX) has today received in Australia the first battery electrode stacks made by its new Thailand facility.

The battery stack is the critical part of the Redflow ZBM2 zinc-bromine flow battery, containing electrodes that charge the battery by “plating” zinc on a membrane and then discharge it by reversing that process, which can sustain 10 kilowatt-hours of energy storage capacity for the battery’s operating life.

At Redflow’s Brisbane headquarters, the Thai-made battery stacks will be installed on ZBM2 battery tank sets (without stacks) which were manufactured last year at the former factory in North America.

Redflow Chairman Brett Johnson said these complete batteries would be tested and then supplied to customers to meet existing orders. “As we manufacture stacks for these approximately 200 tank sets, we will progressively validate high-quality components and sub-assemblies at our factory,” he said.

- Details

- In Redflow

- /

Installed in late 2016, the four 10 kilowatt-hour (kWh) zinc-bromine flow batteries have enabled the ageing offices to become net exporters of electricity to the power grid through the intelligent storage of energy harvested from 114 rooftop photovoltaic solar panels.

Mossel Bay Municipality Electricity and Mechanical Department Senior Manager Charles Geldenhuys said the Redflow energy storage system had exceeded expectations. “We are using more energy now than before the system was implemented,” he said.

More News...

- Redflow produces first battery stacks in Thailand (23 January 2018)

- Redflow continues board renewal (22 December 2017)

- Redflow makes first battery components in Thailand (19 December 2017)

- Redflow reveals Thai battery production timeline (24 November 2017)

- Redflow aims for 250 batteries/month from Thailand (06 November 2017)

- QLD home sets Redflow residential record (30 October 2017)

- Redflow starts installing battery line in Thai factory (26 October 2017)

- Victorian couple live off-grid dream with ZCell (12 October 2017)

- Redflow restructures leadership for growth (27 September 2017)

- South African factory beats power cuts with Redflow batteries (25 September 2017)

- Hi-Tech places second US$600,000 order for Redflow batteries (18 September 2017)

- Redflow chooses Thailand for battery factory (17 August 2017)

- Redflow cashes up to target demand areas (14 July 2017)

- Redflow welcomes safety-first fire rules for batteries (11 July 2017)

- Redflow lauds big battery project for SA (07 July 2017)

- Dutch dairy farm deploys six Redflow batteries (24 May 2017)

- Redflow scores A$800,000 battery sale for tropics (08 May 2017)

- Redflow applauds SA Govt battery policy (14 March 2017)

- Redflow welcomes Tesla’s 100 MWh battery farm pitch (12 March 2017)

- Former Santos CEO joins Redflow board (02 March 2017)

Off the Cuff

Simon Hackett speaks about Formula E racing on ABC Radio Adelaide

Australian renewable energy investor Simon Hackett last week spoke to Radio ABC Adelaide's Afternoons host Sonya Feldhoff about the benefits for replacing the cancelled Adelaide 500 motor race with a...

Read more

Seven simple steps for mental health in time of coronavirus

After the summer bushfires, the coronavirus pandemic and associated economic shutdown, “unprecedented” must be a standout favourite for Macquarie Dictionary’s Word of the Year for 2020. For the first time...

Read more

John Harris talks (a bit) about International Albinism Awareness Day on ABC Radio

John Harris, who has the honorary role of PR guy for the Albinism Fellowship of Australia, was interviewed by Peter Goers on the Evenings show of ABC Radio Adelaide on...

Read more

Start-ups are key to the future of everything

Nigel Lake, Executive Chair of global business advisory firm Pottinger, will tell this week's Myriad start-ups festival in Brisbane, running May 16-19, that Australia needs start-ups to protect its prosperity. Pottinger...

Read moreContact

Impress Media Australia

P: +61 8 8431 4000

E: john@impress.com.au

W: www.impress.com.au

Street:

Impress Media Australia

313 Portrush Road,

Norwood SA 5067

Click here for our location

Postal:

Impress Media Australia

Box 95, Kensington Park

South Australia 5068